Sodium Silicate

Product Details:

- Molecular Weight 122.06 g/mol

- Storage Keep container tightly closed, store in a dry, cool, well-ventilated area

- Form Solution, Solid

- Molecular Formula Na2SiO3

- Other Names Water Glass

- Density 2.4 Gram per cubic centimeter(g/cm3)

- Solubility Soluble in water

- Click to View more

X

Sodium Silicate Price And Quantity

- 200 Kilograms

Sodium Silicate Product Specifications

- 215-687-4

- 99%

- Yes

- Na2SiO3

- Odorless

- 11-13

- Liquid/Crystal

- 283919

- 1.520 (liquid)

- Silicates

- Alkaline

- 1088C

- Sodium Silicate

- 122.06 g/mol

- Solution, Solid

- Keep container tightly closed, store in a dry, cool, well-ventilated area

- Sodium Silicate

- Detergent, paper, ceramics, adhesives, construction, water treatment

- Alkaline

- Soluble in water

- IS 381

- 2.4 Gram per cubic centimeter(g/cm3)

- Industrial

- Industrial Grade

- 1344-09-8

- Water Glass

- Na2SiO3

Sodium Silicate Trade Information

- 10000 Kilograms Per Day

- 1 Days

Product Description

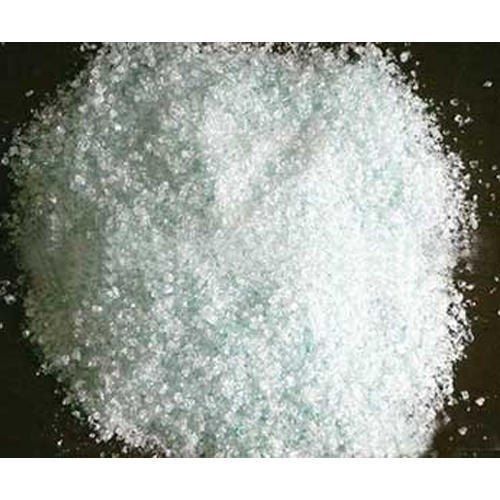

Sodium Silicate is a white colored flaked solid substance which is commonly known as water glass with a molecular formula of Na2SiO3 and an average molar mass of 122.063 grams per mol. This crystalline element is readily soluble in water to produce an alkaline solution. It can be used for the production of various kinds of engineering grade products which includes adhesives, drilling fluids, detergent auxiliary, water treatment chemicals, fire protection elements, constructional and masonry products and any more.

Product details

|

Physical State |

Granules |

|

Grade Standard |

Bio-Tech Grade |

|

Packaging Type |

Bag |

|

Packaging Size |

5-25 kg |

|

Color |

White |

|

Brand |

SGS |

|

Usage/Application |

Laboratory |

Versatile Industrial Applications

Sodium Silicate serves as a multi-purpose solution in numerous industries such as detergents, ceramics, construction, paper production, adhesives, and water treatment processes. Its alkaline nature and strong binding and dispersing properties make it an essential ingredient in these fields, helping to enhance efficiency, product quality, and operational reliability wherever it is applied.

Safe Handling and Storage

Although sodium silicate is non-poisonous, it may irritate the eyes and skin. Proper handling includes the use of appropriate safety gear. Store the material in a cool, dry, well-ventilated area with containers tightly sealed to maintain its stability and effectiveness for its full 24-month shelf life.

FAQs of Sodium Silicate:

Q: How is sodium silicate used in industrial applications?

A: Sodium silicate is commonly added to detergents for cleaning power, incorporated in paper and ceramics manufacturing for binding, used in water treatment for water softening, and included in construction as an adhesive or hardening agent. Its versatility supports a broad spectrum of industrial processes.Q: What are the benefits of using sodium silicate in water treatment?

A: Sodium silicate effectively prevents scale formation, softens water, and aids in coagulation and flocculation processes. Its high alkalinity also helps control pH levels, making it a valuable addition to industrial and municipal water treatment operations.Q: When should sodium silicate be stored and how long does it last?

A: It should be stored immediately upon receipt in a tightly closed container within a cool, dry, and well-ventilated area. Under these conditions, sodium silicate maintains its stability and effectiveness for 24 months from the manufacturing date.Q: Where can sodium silicate be sourced in India?

A: Sodium silicate can be sourced from numerous exporters, importers, manufacturers, suppliers, traders, and wholesalers throughout India who offer it in liquid, solid, or crystalline forms customized for industrial requirements.Q: What is the process for safely handling sodium silicate?

A: When handling sodium silicate, use protective equipment such as gloves and safety goggles to avoid skin or eye irritation. Ensure that the material is handled in a well-ventilated area and that any spills are managed promptly and properly according to safety guidelines.Q: Is sodium silicate compatible with other substances during manufacturing?

A: Yes, sodium silicate is compatible with most cationic and non-ionic substances, making it versatile for blending into various industrial formulations without causing unwanted reactions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free